This year for my birthday I stepped up my 3d printing game from my 3yr old Monoprice Select V2 to a new Ender-5 Plus; huge upgrade after many years of headache.

I was left with what to do with my old printer, certainly too much potential to just throw it away. I thought it too small to be an effective CNC and the novelty of something that could write with a pen was fun but that is a lot of workbench realestate for a toy. Then I realized I could probably turn it into a laser cutter/etcher!

I ordered a 5W laser on the cheap and then waited forever for a boat from China.

Once I got the laser I took detailed measurements of the unit… actually first I freaked out anyone within several miles of my mountain top house by shooting it into the night sky wildly for a while, then I measured it lol. I also dismantled the extruder assembly on the printer leaving the gantry frame ready to accept a new payload and took its measurements as well. I then hopped on Autofusion 360 and designed a mount to connect the two:

I also popped open the electronic box on the laser and to my relief, discovered a connection labelled TTL. This is necessary to turn the laser on and off via the circuitry. The plan was to use the old connection for the fan such that when the GCODE to 3d print indicates fan on, the new laser turns on.

After a bit of testing the various 3d printer extruder and fan connections with my multimeter I made the disappointing discovery that the Select v2 enables its fans by switching the ground rather than switching the power. My expectation is that I would have found the ground on the fan grounded and the power enabled or disabled when the fan was on or off, that would have been incredibly convenient to leverage for the TTL. I considered some approaches to inverting the signal, but I didn’t want to bring another power wire into the equation and complicate the build. So I simply use the TTL inverted, which is to say, fan=on -> laser=off & fan=off -> laser=on. I power the laser from the extruder power, conveniently the correct voltage (12vdc) for my laser, my rationale was that the extruder driver would be most appropriate for the current drawn by the laser versus the fan, but that was just an assumption. With that I wired it up and bolted in to the mount and mount to gantry frame.

All assembled, I could successfully power the laser by turning on the extruder and toggle the laser on or off by enabling or disabling fan 1. Now for getting it to print something….

I followed a guide online to use Inkscape with a plug-in called Inkscape Laser Tool Plug-in . With that installed I quickly discovered that powering up with the extruder and inverted fan signal were going to be a problem. Fortunately I opened up the plugin code (Python) and enhanced it to work for my unit. Specifically when it turns on I have it auto-home, then turn on the fan (laser off) and then turn on the extruder (laser powered), and then print with the inverted laser values. At the end of the print I have it power down the laser.

After that I was able to play around with converting some images to paths and then getting them onto the SD card and into the printer. I experienced a couple of hiccups along the way with the plugin misbehaving but I was able to get through it, it is touch buggy in my experience but it works well enough for me. I am still dialing in the speed of the laser to find the right ranges for etching. The color of the material also plays a role, cutting a white piece of paper vs darker cardboard dramatically affect the right speed.

Here is a video of it first etching something!

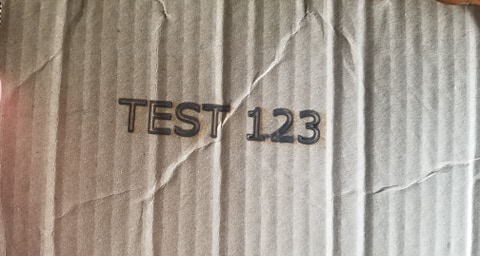

And how that test came out:

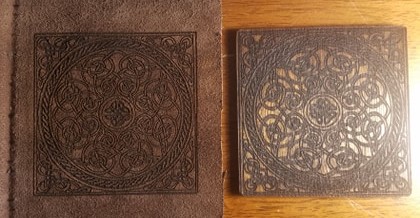

Here is a more elaborate pattern on Leather and Wood, same speed on both but clearly the speed was too slow for the wood and scorched a bit:

Wow ..that’s so great !! Uncle Harry would have loved this xo

On Tue, Jun 16, 2020 at 12:53 PM Rosola Laboratories wrote:

> Michael Rosola posted: “This year for my birthday I stepped up my 3d > printing game from my 3yr old Monoprice Select V2 to a new Ender-5 Plus; > huge upgrade after many years of headache. I was left with what to do with > my old printer, certainly too much potential to just throw it” >

Love ❤️